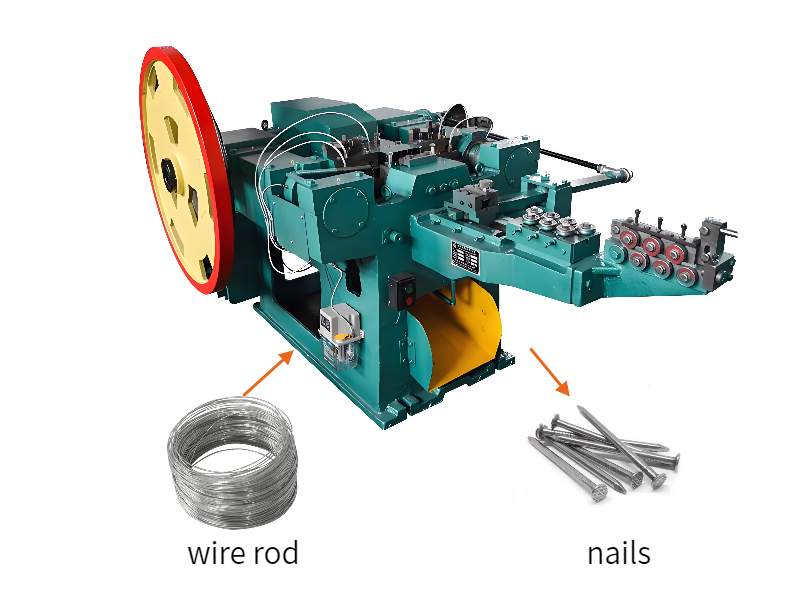

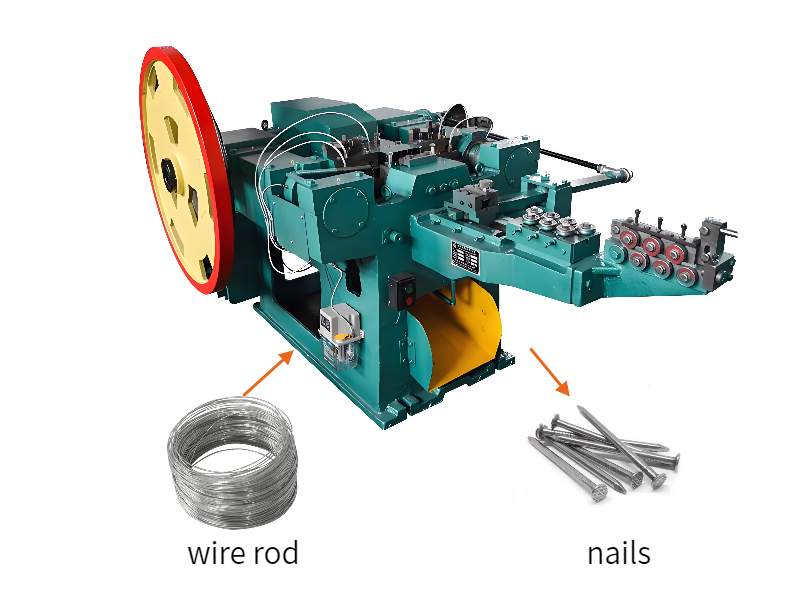

Z94 Nail Making Machine: Leading the New Era of Efficient Production in the Nail Manufacturing Industry

With the rapid development of industries such as construction, furniture, and packaging, the market demand for various types of nails continues to rise. Nail manufacturing enterprises are facing a triple challenge: "meeting production targets, ensuring high product quality, and controlling costs". The emergence of the Z94 Nail Making Machine, with its outstanding performance, user-friendly operation, and stable quality, has become a key equipment for many nail manufacturers to break through production bottlenecks and enhance core competitiveness.

I. Prominent Industry Pain Points: The Z94 Nail Making Machine Emerges as a Solution

The current nail manufacturing industry generally faces three major pain points: First, traditional nail making equipment operates at a slow speed, often leading to "rush work anxiety" when dealing with large orders, making it difficult to guarantee delivery cycles. Second, excessive manual intervention results in frequent quality issues such as nail size deviations and unstable nail heads, leading to high rejection rates and raw material waste. Third, complex equipment structures increase maintenance difficulty; once a breakdown occurs, long downtime for repairs directly affects production progress.

Targeting these industry-wide problems, the Z94 Nail Making Machine achieves the organic integration of "speed, quality, and maintenance" through innovative design and technological upgrades. It not only significantly improves production efficiency and strictly controls product quality but also reduces maintenance costs and complexity, solving critical concerns for nail manufacturing enterprises.

II. Core Performance Analysis: Four Major Advantages of the Z94 Nail Making Machine

1. High Speed & Efficiency: Double Production Capacity Easily

The Z94 Nail Making Machine adopts advanced automatic feeding and stamping technology, breaking the speed limitations of traditional equipment. It can produce up to 60 nails per minute (production capacity varies slightly depending on nail diameter, which ranges from 1.6mm to 4.0mm), with a maximum hourly output of 3,600 nails. Compared to a 30% efficiency improvement over traditional nail making machines, it can easily meet the demands of large-volume orders.

Take a small-to-medium-sized nail workshop as an example: a 100,000-piece order for ordinary construction nails that previously took 3 days to complete can now be finished in just 1.5 days with the Z94 Nail Making Machine. This not only shortens the delivery cycle but also frees up time to take on more orders, directly increasing corporate revenue.

2. Precision Control: Stable and Reliable Quality

Quality is the lifeline of nail manufacturing enterprises, and the Z94 Nail Making Machine excels in quality control. Equipped with a high-precision adjustable die head, it can accurately control nail length, diameter, and head shape, ensuring that the size error of each nail does not exceed 0.1mm. Meanwhile, the automatic feeding system avoids deviations caused by manual feeding, reducing the production of defective products such as "crooked nails" and "broken nails".

Practical tests show that the rejection rate of nails produced by the Z94 Nail Making Machine can drop from over 10% (with traditional equipment) to less than 2%, significantly reducing raw material waste. In addition, the low-carbon steel wire processing technology adopted by the equipment ensures the tensile strength and toughness of nails, complying with quality standards for construction, furniture, and other industries, eliminating concerns about customer complaints due to quality issues.

3. User-Friendly Operation: Low Entry Threshold

For many nail manufacturers, "difficult equipment operation requiring professional technicians" is a major hassle. The Z94 Nail Making Machine features a humanized design with a clear and intuitive control panel. Daily operations can be completed using just three core buttons: "Start/Stop", "Speed Adjustment", and "Emergency Shutdown". Even inexperienced new employees can master independent operation after only 1-2 hours of simple training.

Additionally, the compact size of the equipment (approximately 1200mm × 800mm × 1500mm) saves workshop space. Whether in small workshops or large factories, it can be flexibly placed to maximize the use of production areas.

4. Durability & Robustness: Low Maintenance Costs

The service life and maintenance costs of nail making equipment directly impact long-term corporate investment. The Z94 Nail Making Machine stands out in durability: its frame is made of 10mm-thick high-strength steel, which can withstand vibration and impact during long-term operation without deformation. Key components such as die heads and punches are made of wear-resistant alloy materials, extending their service life by more than 50% compared to ordinary parts.

In terms of maintenance, the Z94 Nail Making Machine has a simple structural design with easily removable side panels and clearly labeled internal components. Daily cleaning, lubrication, and replacement of wearing parts can be completed by on-site staff without the need for professional maintenance personnel. Statistics show that the annual maintenance cost of the Z94 Nail Making Machine is only half that of traditional equipment. With proper maintenance, the equipment can operate stably for 5-8 years, delivering an ROI far exceeding the industry average.

III. Wide Application Scenarios: Meeting Diverse Needs

With its excellent versatility, the Z94 Nail Making Machine can adapt to the needs of nail manufacturing enterprises of different sizes and types:

Custom Nail Manufacturers: By replacing molds of different specifications, the Z94 Nail Making Machine can produce various types of nails (ordinary nails, finishing nails, roofing nails, etc.), eliminating the need to purchase separate equipment for different products and reducing corporate investment costs.

Start-Up Nail Enterprises: With its affordable price, simple operation, and convenient maintenance, the equipment helps entrepreneurs launch their businesses quickly and reduce start-up risks.

IV. User Cases: The Z94 Nail Making Machine Drives Enterprise Growth

Case 1: Efficiency Revolution in a Mexican Construction Fastener Factory

Carlos M. is the owner of a construction fastener factory in Mexico. Previously, due to outdated equipment, the factory could only produce 1.5 million nails per month, failing to meet the needs of the local construction industry. After introducing the Z94 Nail Making Machine in 2023, monthly production capacity increased to 2.5 million nails, and the rejection rate dropped from 12% to 1.8%. "The Z94 Nail Making Machine not only helped us secure more large orders but also improved our reputation in the local market. Now, three large construction companies have taken the initiative to cooperate with us," said Carlos M. in an interview.

Case 2: A "Start-Up Tool" for a New Workshop in China

In early 2024, Li J. founded a small nail workshop in Zhejiang Province, initially investing in only one Z94 Nail Making Machine. "At first, I was worried that I couldn’t operate the equipment due to lack of experience, but I mastered it in half a day," Li J. said. The workshop produces 800,000 nails per month, mainly supplying local furniture factories, and recovered the equipment investment cost in less than six months. "Now, with more and more orders, I plan to purchase another Z94 Nail Making Machine to expand production scale."

V. Choosing a Reliable Supplier: Ensuring Equipment Value

High-quality equipment requires matching reliable supplier services to maximize its value. When selecting a supplier for the Z94 Nail Making Machine, it is recommended to focus on the following three points:

Quality Assurance: Confirm whether the supplier conducts strict factory inspections on equipment and provides warranties for core components (e.g., a 12-month warranty).

Service Capability: Understand whether the supplier offers installation guidance, operation training, and 24/7 after-sales support to ensure timely resolution of equipment issues.

Cost-Effectiveness: Prioritize suppliers that provide direct factory sales to avoid price markups by middlemen. Meanwhile, compare equipment configurations and prices to select cost-effective products that meet your specific needs.

Conclusion

In today’s increasingly competitive nail manufacturing industry, the Z94 Nail Making Machine, with its core advantages of "high speed, high quality, user-friendliness, and durability", has become an important tool for enterprises to improve production efficiency, reduce operating costs, and enhance market competitiveness. Whether you are an established enterprise looking to expand capacity or a new workshop just starting out, choosing the Z94 Nail Making Machine will help you seize opportunities in the development of the nail manufacturing industry and achieve sustainable growth.

![]() 中文

中文