In the fastener industry, coil nails are key consumables for automated nailing, offering core advantages of continuous feeding and high efficiency. Formed by bonding individual nails into coils via adhesive or wire, they work with coil nail guns for uninterrupted operation, significantly boosting efficiency in wood processing, construction, and logistics packaging. Compared to traditional loose nails, they reduce reloading time and ensure nailing precision, making them ideal for heavy-load fixing and mass production. This article comprehensively analyzes coil nail classifications (by structure, material, and application) and their typical use scenarios.

I. Classification by Structure and Connection Method: Adapting to Different Operation Precision Requirements

Coil nail structure directly affects feeding stability, residues, and surface finish. They are mainly divided into adhesive-bonded and wire-connected types, with distinct characteristics and applications.

(1) Adhesive-Bonded Coil Nails: The Preferred Choice for Precision Operations

Adhesive-bonded coil nails are made by gluing individual round nails into coils with eco-friendly adhesive. Featuring smooth shanks and no metal connectors, they leave no wire residues, create small flat nail holes, and enable smooth feeding with medium-low power nail guns.

They are suitable for precision-demanding fields: furniture assembly, cabinet fixing, decorative line installation, fine woodworking (board splicing, tenon-and-mortise auxiliary fixing), gift packaging, and interior decoration (lightweight board and skirting line fixing) due to their trace-free effect.

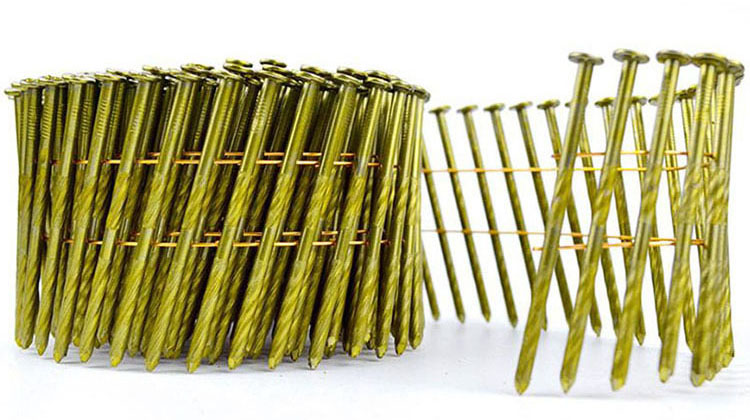

(2) Wire-Connected Coil Nails: The Core Support for Heavy-Load Scenarios

Wire-connected coil nails use high-strength wire to link nails at the cap, offering much higher connection strength for high-frequency, high-intensity operations with high-power nail guns. They have strong tensile strength, ensuring stable fixing in high-density wood or heavy-load scenarios, though minor wire residues require post-cleaning.

Typical applications include heavy-load scenarios: wooden pallet/skid manufacturing, heavy goods packaging, wooden structure building (beam-column connection, roof purlin fixing), scaffolding installation, container floor fitting, and large formwork fixing, enhancing efficiency and quality.

II. Classification by Material and Surface Treatment: Adapting to Different Environmental Weather Resistance Requirements

Coil nail material and surface treatment determine corrosion resistance, rust resistance, and service life. They are categorized into ordinary carbon steel, galvanized, and stainless steel types for dry indoor, outdoor humid, and harsh corrosive environments respectively.

(1) Ordinary Carbon Steel Coil Nails: An Economical and Practical Choice for Indoor Use

Ordinary carbon steel coil nails are cost-effective, with moderate hardness and good processability for dry indoor use. However, they lack rust resistance, making them unsuitable for humid/outdoor environments.

Applications: disposable wooden boxes, temporary construction fixing, auxiliary indoor furniture fixing, and short-term lightweight board fixing, leveraging high cost-performance in dry, short-service-life scenarios.

(2) Galvanized Coil Nails: The Preferred Choice for Rust and Moisture Prevention Outdoors

Galvanized coil nails (hot-dip or electro-galvanized) have a protective layer against air and moisture, with superior corrosion resistance. Hot-dip galvanized types (thicker layer, longer life) suit long-term outdoor use; electro-galvanized types (thinner layer, lower cost) for mild humidity.

Applications: outdoor wooden structures, open-air shelves, garden fences, outdoor billboards, marine pallets, container packaging, and indoor humid areas (bathrooms, kitchens) for moisture and rust prevention.

(3) Stainless Steel Coil Nails: Suitable for Harsh Corrosive Environments

Stainless steel coil nails (304/316) offer excellent acid-alkali and corrosion resistance for long-term use in harsh environments (coastal salt spray, chemical corrosion, high temperature/humidity). 316 types suit extreme corrosion; 304 types for general corrosion with better cost-performance.

Applications: coastal construction, chemical equipment packaging, food processing workshop shelves, high-end outdoor furniture, and mariculture equipment, ensuring structural safety and long service life.

III. Classification by Application and Nail Type: Precisely Matching Industry-Specific Needs

Coil nails can also be subdivided by application and specification, with optimized length, diameter, and cap design to match industry-specific needs.

(1) Pallet Coil Nails: The Main Consumable in the Logistics Packaging Industry

Pallet coil nails (50-100mm long, 2.8-3.8mm diameter) are mainly wire-connected for wooden pallet/skid production. Threaded shanks are optional to enhance wood bite force and prevent loosening during heavy load/handling.

Core application: fixing pallet panels and supporting squares, a key fastener in logistics packaging and warehousing, improving production efficiency and load-bearing stability.

(2) Furniture Coil Nails: Special Consumables for Fine Woodworking

Furniture coil nails (20-50mm long, 1.8-2.5mm diameter) are mostly adhesive-bonded with countersunk caps, ensuring no residues and aesthetic surfaces for furniture manufacturing.

Core applications: panel furniture assembly, cabinet backplane fixing, drawer guide installation, decorative line fitting, and sofa frame auxiliary fixing, ensuring assembly precision and surface integrity in high-end furniture production.

(3) Construction Coil Nails: Heavy-Load Consumables for Engineering Construction

Construction coil nails (80-150mm long, 3.5-4.2mm diameter) are wire-connected, high-strength carbon steel (some quenched) for construction, compatible with high-power nail guns to penetrate dense materials.

Core applications: wooden structure beam-column connection, roof panel fixing, scaffolding installation, formwork fitting, and outdoor anti-corrosion wood projects, enhancing construction efficiency and structural stability.

IV. Summary of Coil Nail Classification and Application Scenario Adaptation

Coil nail classification aligns with operation, environmental, and industry requirements. A summary of core advantages and typical applications is provided below for quick selection:

Coil Nail Type | Core Advantages | Typical Application Industries |

Adhesive-Bonded Coil Nails | No wire residues, small nail holes, aesthetic surface, smooth feeding | Furniture manufacturing, fine woodworking, decoration, gift packaging |

Wire-Connected Coil Nails | Firm connection, strong tensile strength, suitable for high-intensity operations, anti-jamming | Logistics packaging, construction, container manufacturing, pallet production |

Ordinary Carbon Steel Coil Nails | Low cost, moderate hardness, good processability | Indoor disposable packaging, temporary construction, auxiliary furniture fixing |

Galvanized Coil Nails | Rust/moisture prevention, strong corrosion resistance, suitable for outdoor humidity | Outdoor engineering, garden facilities, marine packaging, open-air shelves |

Stainless Steel Coil Nails | Acid-alkali/corrosion resistance, suitable for harsh environments, long service life | Coastal construction, chemical packaging, food processing, high-end outdoor furniture |

Pallet Coil Nails | Long shank, strong bite force, suitable for heavy-load fixing | Logistics packaging, warehousing, pallet manufacturing |

Furniture Coil Nails | Thin shank, small nail holes, countersunk head, aesthetic surface | Furniture manufacturing, cabinet assembly, decoration |

Construction Coil Nails | Thick shank, high strength, suitable for high-power equipment, strong penetration | Construction, wooden structures, scaffolding, outdoor engineering |

V. Conclusion

Coil nail classification responds precisely to diverse operational needs, with each type tailored to specific requirements. Users should select appropriate types based on precision, environment, and load-bearing demands to maximize efficiency and stability. As automated nailing equipment becomes prevalent, coil nail applications will expand, and the classification system will be further refined to provide precise fastening solutions for more industries.

![]() 中文

中文