Tel: +86 18255112898

Email: salehongfeng@163.com

![]() 中文

中文

Low Carbon Steel Wire Mesh: King of Cost-Effectiveness

High Carbon Steel Wire Mesh: Leader in High Strength

Stainless Steel Wire Mesh: Ceiling of Corrosion Resistance

Galvanized Steel Wire Mesh: Preferred for Outdoor Use

Special Material Steel Wire Mesh: Niche High-End Types

PVC-coated Steel Wire Mesh: Covered with a PVC layer on the surface, available in various colors (black, green, white, etc.), scratch-resistant and aesthetically pleasing, suitable for garden fencing and pet cages;

Alloy Steel Wire Mesh: Can withstand high temperature and pressure, suitable for the protection needs of industrial high-temperature equipment;

Copper/Brass Wire Mesh: Good electrical conductivity, often used for electronic equipment shielding or high-end architectural decoration, combining appearance and strength.

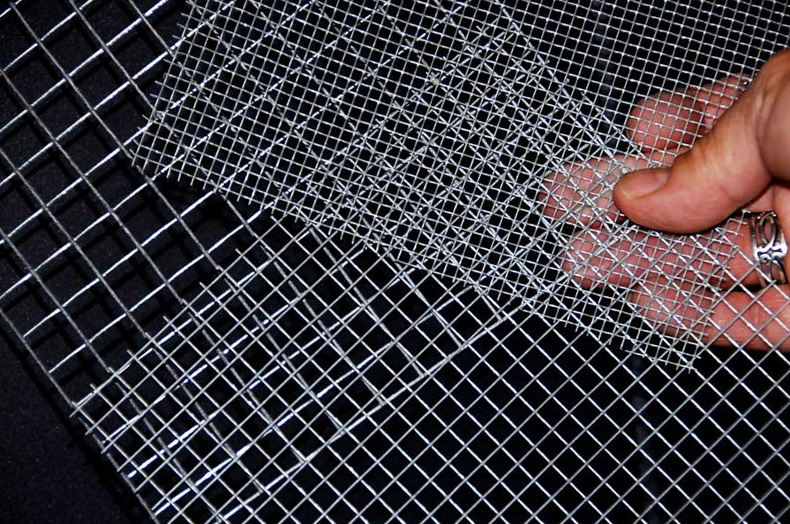

Woven Mesh: Formed by cross-weaving warp and weft steel wires, with uniform mesh and good elasticity. Breeding nets, filter nets, and decorative nets all belong to this category, suitable for scenarios requiring "flexible protection";

Welded Mesh: Steel wires are fixed by resistance spot welding, with a firm structure and strong integrity. Construction protection nets, fencing nets, and shelf nets mostly adopt welding technology, suitable for scenarios requiring "rigid support";

Stamped Mesh: Formed by stamping with molds, the mesh shape can be customized (circular, square, special-shaped). Screen nets and mechanical protection nets often use this process, adapting to the needs of "precision screening" or "special shape protection";

Crimped Mesh: High-strength steel wires are crimped before weaving, wear-resistant and pressure-resistant. For material screening scenarios in mining, coal, and chemical industries, it can withstand high-frequency wear.

Plastering Mesh: Embedded in the wall plaster layer, specially solving the problem of wall cracking and peeling. It is an "anti-cracking must-have" for the construction of residential buildings, office buildings, and bridges;

Scaffolding Safety Mesh: Surrounded outside the scaffolding to form a protective barrier, safeguarding the safety bottom line of construction workers;

Steel Mesh Sheets: Formed by welding high carbon steel wires and embedded in concrete, it can significantly improve the bearing capacity and seismic performance of floors, pavements, and bridges, making buildings more solid.

Greenhouse Mesh: Either galvanized steel wire mesh for corrosion resistance or PVC-coated steel wire mesh for better appearance. It can be used as both fencing and insect nets, achieving both ventilation and protection;

Breeding Fencing Mesh: The mesh size can be customized according to the size of livestock and poultry such as chickens, ducks, pigs, and sheep, preventing animals from escaping and blocking the invasion of natural enemies, making breeding more worry-free;

Orchard Protection Mesh: Made of high-strength galvanized steel wire mesh, it can prevent bird pecking and hail damage, avoiding fruit loss and ensuring orchard yield and quality.

Screening Filter Mesh: Woven from stainless steel or high carbon steel wire. Mines screen coal, food factories filter flour, and chemical plants separate raw materials, all relying on it to achieve precise classification;

Mechanical Protection Mesh: Made of welded mesh or stamped mesh, covering the shells of machine tools, motors, and other equipment to prevent human contact with dangerous components and ensure production safety;

Environmental Protection Filter Mesh: Stainless steel material is corrosion-resistant and durable, used for sewage treatment and waste gas purification, intercepting impurities and filtering pollutants, assisting green production.

Road Fencing Mesh: Made of galvanized steel wire or stainless steel through welding, used for highways, municipal roads, and community walls to divide areas, standardize order and ensure safety;

Anti-theft Mesh: Woven from high carbon steel wire or stainless steel, installed on doors, windows, and balconies, it can effectively block theft and add an extra layer of safety protection for families;

Marine Engineering Mesh: Made of 316L stainless steel material, resistant to salt spray corrosion, adapting to the harsh environment of offshore platforms and ports, and not easy to rust after long-term use.

Food and Medical Field: 304/316 stainless steel wire mesh meets food-grade and medical-grade standards, free from rust pollution. Used for food processing protection and medical equipment protection, it is safe and environmentally friendly;

Electronic and Decoration Field: Copper wire mesh can shield electromagnetic signals and protect electronic equipment from normal operation; brass wire mesh and stainless steel decorative mesh are used in architectural decoration and furniture design to enhance the appearance.

First Determine the Scenario: Choose the Material According to the Environment

Then Verify Parameters: Determine Specifications According to Needs

Check Quality: Verify Materials According to Standards

Key Differences Between Cold-Galvanized Iron Wir

Coil Nails

Contact: Fan

Phone: +86 18255112898

Tel: 0551-82311088

Email: salehongfeng@163.com

Add: No. 8, Circular Economy Industrial Park, Zhangpu Town, Tianchang City, Chuzhou City

We chat