Tel: +86 18255112898

Email: salehongfeng@163.com

![]() 中文

中文

Steel Bar Binding and Reinforcement: Low-carbon iron wire of grades Q195 and Q235 (wire diameter 1.2-3.0mm) is the "standard configuration" for concrete projects. It is used to accurately bind and fix steel bar frames, preventing displacement and deformation of steel bars during concrete pouring. According to industry data, approximately 300-500kg of such iron wire is consumed per 1,000㎡ of high-rise building construction. In large-scale infrastructure projects such as Ho Chi Minh City New Airport in Southeast Asia's Vietnam and Lagos Cross-Sea Bridge in Africa's Nigeria, its ability to be manually bent without professional tools makes it an "accelerator" for on-site construction efficiency, accounting for over 40% of local annual iron wire demand.

Construction Protection and Support: Thick-gauge iron wire (3.0-6.0mm) is woven and welded into scaffolding safety nets and construction guardrails, with a tensile strength of 350-450MPa, capable of withstanding impact loads exceeding 200kg, building a safety barrier for high-altitude workers. Fine iron wire (0.8-1.5mm) is used to fix wall pipelines and ceiling keels, with an error controlled within ±0.5mm, ensuring the precision of decoration and construction.

: Iron wire subjected to surface treatments such as hot-dip galvanizing (zinc coating thickness 80-200g/㎡) and plastic coating can be processed into architectural decorative nets, balcony railings, staircase handrails, etc., combining corrosion resistance and aesthetic value. In high-end residential projects on Dubai's Palm Jumeirah in the Middle East, galvanized iron wire decorative nets are preferred for exterior wall decoration and privacy protection due to their salt spray corrosion resistance and delicate texture, with a service life of over 15 years.

Crop Support and Shaping: In vegetable greenhouses and orchard planting, fine iron wire (0.8-2.0mm) is used to build growth supports for climbing crops (cucumbers, grapes, passion fruits), capable of bearing a single plant weight of 5-8kg. It helps plants grow upward, increasing ventilation and light transmission by over 30% and per mu yield by 15%-20%. Meanwhile, it can be customized into horticultural fences and flower pot stands, adapting to the standardized management needs of home balcony gardening and ten-thousand-mu scale farms.

Breeding Protection and Isolation: Hot-dip galvanized or electro-galvanized iron wire (wire diameter 2.0-4.0mm) is the core material for breeding fences, chicken coops, rabbit hutches, and fishing net frames. With a zinc coating adhesion of grade 3 or higher, it can resist wind and rain in outdoor environments. In Brazil's soybean plantations in South America and Poland's poultry farms in Eastern Europe, its service life reaches 5-8 years, 3 times longer than ordinary iron wire, significantly reducing the maintenance cost of breeding facilities.

Crop Harvesting and Storage: Soft low-carbon iron wire (elongation ≥18%) is used to bind crop straws and branches, capable of being bent 180° without breaking, avoiding damage to crop straws and facilitating mechanized harvesting, storage, and transportation. It saves 2-3 hours of manual binding time per mu of land, becoming a "valuable assistant" for large-scale agricultural operations.

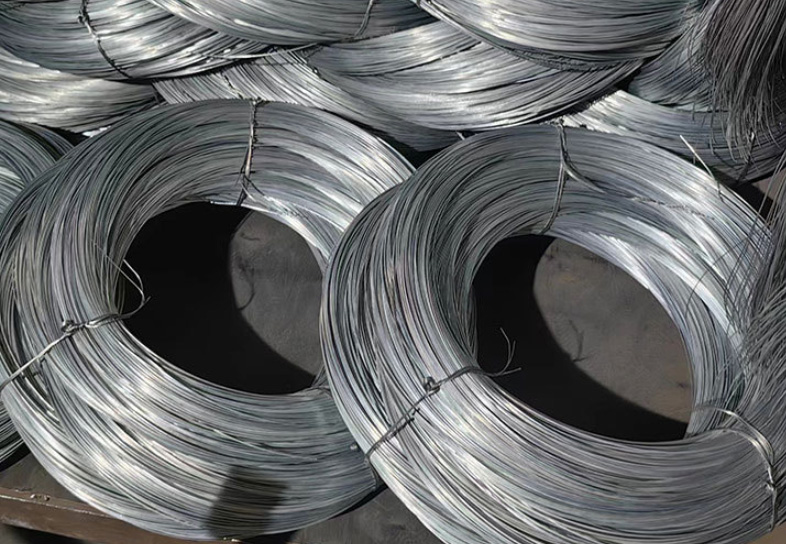

Bulk Commodity Binding: Thick iron wire (2.5-6.0mm) is used to bind heavy goods such as steel, wood, pipes, and stone. A single wire can bear a tensile force of 500-800kg. In container shipping, it can firmly fix goods, preventing damage caused by displacement due to jolting during transportation. Such iron wire is mostly supplied in large coils of 100kg/200kg, reducing sea shipping and warehousing costs, and is favored by Chinese building material exporters and global logistics companies, with a global annual consumption exceeding 10 million tons.

Sealing of Scattered Goods: Fine iron wire (0.5-1.5mm) is used for sealing and binding heavy cartons and woven bags. Its binding strength is 3-5 times that of ordinary tape, and it is not prone to aging, resisting high and low temperatures (-20℃ to 60℃). Widely used in the packaging of heavy goods such as home appliances and mechanical parts, the utilization rate of iron wire in the global logistics industry exceeds 65%.

Special Protective Packaging: PVC/PE plastic-coated iron wire, with a soft surface and no sharp edges, is specially used for packaging and binding fragile items, furniture, and precision instruments. It can effectively avoid scratching the surface of goods during binding, meeting the strict requirements for packaging protection in European and American markets, and becoming the "standard packaging material" for high-end goods export.

Core Raw Material for Hardware Products: Iron wire is the "source material" for fasteners such as iron nails, screws, and nuts. Through processes like wire drawing, straightening, cutting, and shaping, it can be made into hardware parts of different specifications (1.0-6.0mm), adapting to scenarios such as furniture manufacturing, mechanical assembly, and decoration maintenance. Meanwhile, it can be processed into steel wire brushes, iron wire cages, welded wire mesh, woven wire mesh, etc., used in industrial cleaning, warehousing protection, water filtration, and other fields, with a utilization rate of over 70% in the global hardware industry.

Carrier for Daily Necessities and Crafts: Fine iron wire (0.3-1.0mm) can be made into household items such as clothes hangers, curtain rods, and towel racks with its excellent plasticity, combining practicality and minimalist aesthetics. In the craft industry, after bending, welding, and painting, it can be crafted into iron art ornaments, holiday decorations, handmade jewelry, etc. In European, American, Japanese, and South Korean markets, the annual sales volume of such iron wire crafts exceeds 1 billion US dollars, making it a "popular material" in the field of handmade creation.

Substrate for Small Accessories and Springs: Soft low-carbon iron wire can be made into toy springs, office supply springs, small automotive parts, etc., through annealing and winding processes. Its elastic modulus can be precisely adjusted through processing techniques (190-210GPa), adapting to the performance requirements of different products, with an application proportion of over 30% in the toy and automotive parts industries.

Medical Assistance Field: Ultra-fine medical iron wire (less than 0.1mm in diameter), after biocompatibility treatment, can be used to manufacture medical stents, surgical suture auxiliary materials, etc., with a dimensional accuracy controlled within ±0.005mm, meeting the FDA and CE certification standards of the medical device industry and providing key support for minimally invasive surgery.

Mining and Tunnel Protection: High-strength iron wire (tensile strength ≥600MPa) is used to make warp and weft nets for coal mine support and tunnel protection nets, featuring wear resistance and impact resistance. In China's Shanxi coal mines and Sichuan-Tibet Railway tunnel construction, it has effectively reduced the risk of collapse and ensured construction safety.

Emergency Rescue Scenarios: In emergency situations such as natural disasters and vehicle breakdowns, thick iron wire can be used as a temporary fixing tool and shelter frame. Its durability can cope with complex and harsh environments, making it an "important member" of emergency rescue supplies.

Outstanding Cost Advantage: Abundant supply of low-carbon steel raw materials and mature production processes make iron wire only 1/5 the price of copper wire and 1/3 the price of aluminum wire. It is suitable for bulk procurement and large-scale applications, making it the preferred choice for customers pursuing cost-effectiveness.

Excellent Processability: Easy to bend, weld, and cut, iron wire can be processed into products of different wire diameters (0.3-6.0mm) and surface states through wire drawing, annealing, galvanizing, plastic coating, and other processes, adapting to diverse needs from precision manufacturing to extensive operations.

Strong Durability and Adaptability<span data-string="true" style="outline: none; -webkit-font-smoo

Key Differences Between Cold-Galvanized Iron Wir

Coil Nails

Plastic Strip Nail Gun

Contact: Fan

Phone: +86 18255112898

Tel: 0551-82311088

Email: salehongfeng@163.com

Add: No. 8, Circular Economy Industrial Park, Zhangpu Town, Tianchang City, Chuzhou City

We chat